A fire event is a crisis that calls for fast and forceful response from both human and mechanical defenses. Unlike a conventional water works or irrigation scenario where there is plenty of time to start a hydraulic system up slowly, a fire emergency calls for rapid and immediate engagement of the system.

Typically the water is turned all the way on instantly and the pump is expected to start working at full force immediately. This sends shock waves throughout the entire system. The resulting water hammer effect can easily damage system parts, including pipes, pumps, connectors and valves. As a rule of thumb the potential surge pressure can reach in bars,10 times the water velocity in meters per second, therefore at 5ms (15 fps) the potential surge is at least 50 bars (750 psi). It’s critical that every component in a fire protection system be durable and reliable enough to stand up to the kind of action a fire situation requires. One component that often goes overlooked is the fire protection valve. Most hydraulic/elastomeric fire protection valves were originally designed for waterworks applications or even irrigation. While this can be mostly sufficient it’s not ideal. Deluge valves are exposed to specific stresses and conditions that are rarely encountered in other situations. For instance, water pressure surges and flow rates are typically much higher in a fire protection application than you would find in other fluid/water system.

It’s critical that every component in a fire protection system be durable and reliable enough to stand up to the kind of action a fire situation requires. One component that often goes overlooked is the fire protection valve. Most hydraulic/elastomeric fire protection valves were originally designed for waterworks applications or even irrigation. While this can be mostly sufficient it’s not ideal. Deluge valves are exposed to specific stresses and conditions that are rarely encountered in other situations. For instance, water pressure surges and flow rates are typically much higher in a fire protection application than you would find in other fluid/water system.

Deluge Valves Designed to Hold Up to Fire Protection Applications

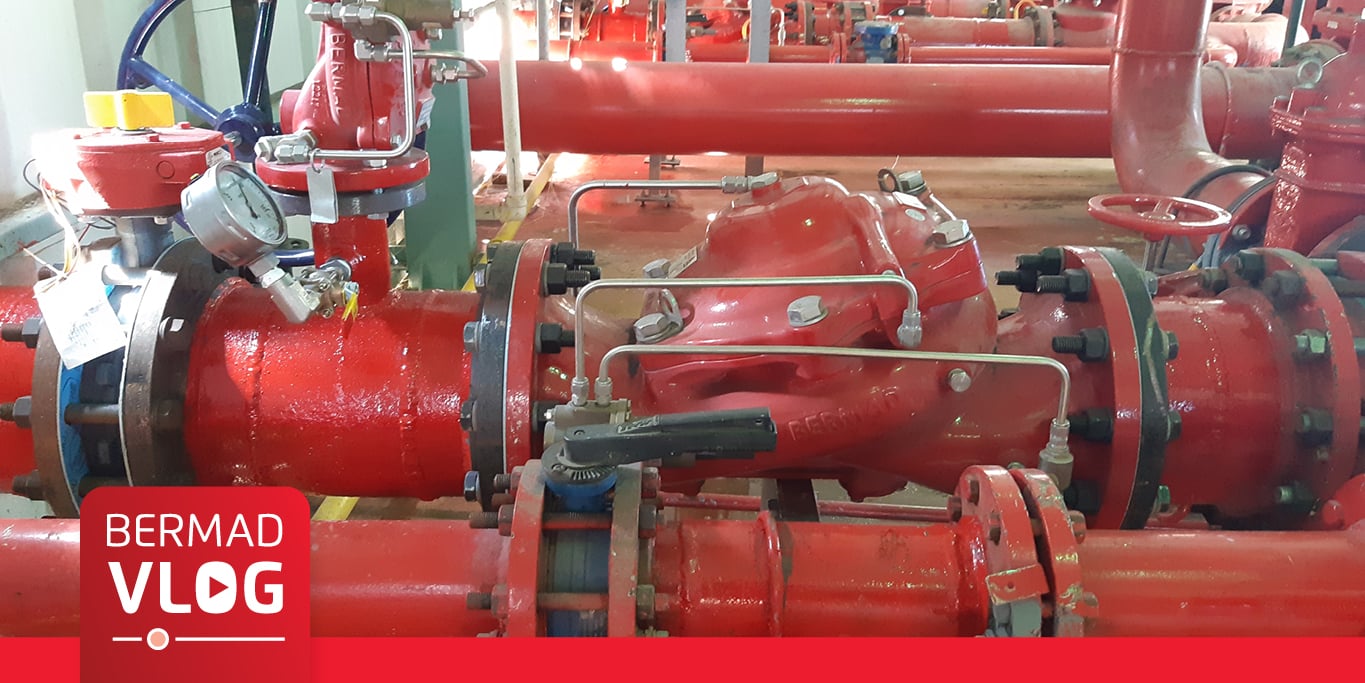

The BERMAD 400Y Torrent series valve is one of the few deluge valves on the market specifically designed for fire protection from the very beginning. The exceptional high flow and rugged design creates virtually zero mechanical friction and contains only one moving part, this valve is engineered for extreme longevity and unsurpassed reliability in the field.

At the heart of the 400Y is a uniquely designed peripherally supported fiber-reinforced vulcanized rubber diaphragm with an encapsulated radial seal disk. This feature combines the best of two different types of valve design. The metal disc gives the valve unsurpassed strength and pressure holding capability so it can hold up to the rigorous demands of fire protection systems where a valve has to lay dormant and pressurized for long periods. The elastomeric diaphragm itself contributes frictionless actuation, unobstructed flow and reliable opening performance. Combined, the two come together in a single-piece unit that results in long-lasting and dependable performance, even under harsh conditions.

These features result in a tough, durable valve that can withstand significantly greater water pressures than a standard water control valve. The 400Y is rated at up to 25 bar (365 psi) of pressure; however, the valve has been tested to hold pressure of 125 bar (1815 psi), ensuring a high resistance to surge and water hammer.

The 400Y Torrent Valve is also designed to stand up to virtually any kind of harsh or corrosive fluids found in fire protection systems and environments. These include foam solutions and concentrates, seawater, UV light and other corrosive elements that may come into contact with the internal or external surfaces of the valve.

The ruggedly constructed valve body can be manufactured from a wide range of corrosion-resistant materials have different coatings applied to suit specific conditions and locations. For example, a valve used in a fire protection system designed for use on an offshore oil rig needs to be able to withstand direct sunlight and seawater. In such an application, selecting a salt-resistant body material such as titanium would be appropriate. A tunnel situation, in contrast, may call for a special coating on the interior of the valve to stand up to long-term exposure to foam concentrates.

Safety and Compliance

The 400Y Torrent Valve meets and/or exceeds almost all applicable regulatory and safety standards. It is UL listed and FM Approved when installed appropriately, and also carries the Type Approval of ABS, Lloyds Register and DNV. Listings and certifications may vary by industry application type.