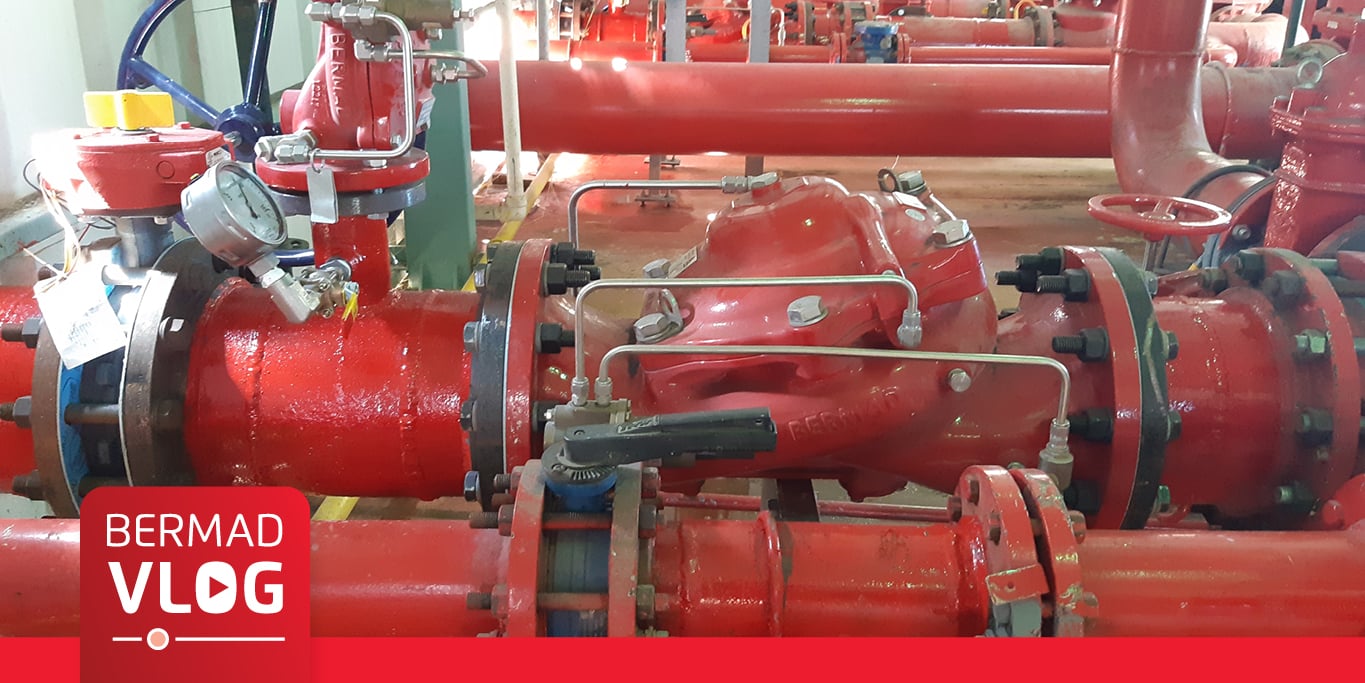

Deluge systems are active fire protection measures that consist of three main components: a Deluge Valve, ancillary distribution pipework and open nozzles or fire-monitor. The Deluge Valve is the most important part of the system and is largely responsible for ensuring that an adequate water flow is applied to the fire-impacted area in a short period of time.

Deluge systems are used in many industrial applications. They form an essential element in the design of plants required to handle hazardous and flammable materials in oil and gas facilities, petrochemical plants, refineries, etc. Apart from containing fire, their role is often to cool surfaces of the plant and equipment to prevent structural failure.

Selecting the Right Deluge Valve

When it comes to implementing a Deluge Valve for a fire protection system, operators have a number of different options to choose from - each of which provides its own unique advantages or disadvantages with regards to performance, reliability, response time, maintenance, and flow capacity. Selecting the right valve design is critical to preserving safety and ensuring that the deluge system performs optimally throughout its designated life.

The purpose of this blog/infographic is to help operators make that decision by discussing the pros and cons of some of the most commonly used deluge valves.

Here is what you need to know.

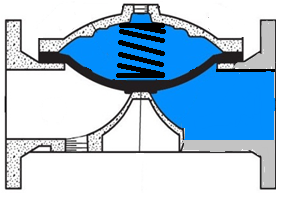

Weir Diaphragm Deluge Valve type

A typical diaphragm valve, which aligns with a seat situated within the body of the valve to create a seal. The advantage with this type of valve is that the valve is very simple for manufacturing doesn’t need to be taken out of the line service for repair.

A typical diaphragm valve, which aligns with a seat situated within the body of the valve to create a seal. The advantage with this type of valve is that the valve is very simple for manufacturing doesn’t need to be taken out of the line service for repair.

The main disadvantage of this valve is that the unsupported diaphragm is highly stressed on the downstream side, restricting the ability of the valve to hold higher pressures for long periods, making maintenance more frequent than with comparable technologies. Also because of the diaphragm flexibility a true position indication of the valve is not possible.

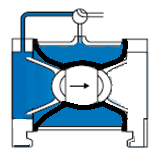

Sleeve/Tubular Deluge Valve

In a tubular diaphragm valve, the diaphragm forms a sleeve within the valve body and is enclosed by a control chamber. When pressure is applied to the chamber, the tube is forced around a cylindrical seat to form a tight seal. The seat is supported by ribs within the valve body, but only on the downstream end. This arrangement leaves the diaphragm vulnerable to damage over time on the upstream side, with consequent valve leakage.

In a tubular diaphragm valve, the diaphragm forms a sleeve within the valve body and is enclosed by a control chamber. When pressure is applied to the chamber, the tube is forced around a cylindrical seat to form a tight seal. The seat is supported by ribs within the valve body, but only on the downstream end. This arrangement leaves the diaphragm vulnerable to damage over time on the upstream side, with consequent valve leakage.

One advantage of the tubular diaphragm valve is that there are no moving parts aside from the tube diaphragm. This design improves linear flow through the valve, but the supporting ribs do provide some obstruction to flow. Additionally, these valves cannot be serviced in-line, which increases downtime. They also have limited functionality for pressure control.

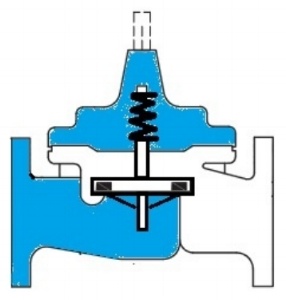

Globe Deluge Valve

A globe valve gets its name from the shape of its body. It consists of a movable disk which provides a seal with a stationary seat within the valve body. Globe valves usually provide excellent sealing for high and low pressures, and can also give a true valve position indication.

A globe valve gets its name from the shape of its body. It consists of a movable disk which provides a seal with a stationary seat within the valve body. Globe valves usually provide excellent sealing for high and low pressures, and can also give a true valve position indication.

This valve has several mechanical parts which all need to be disassembled for service, resulting in increased downtime. The globe valve typically has high-pressure loss due to the complicated flowpath, also often obstructed by the seat arrangement. Different variations of globe valves can often be found to suit the needs of specific deluge system applications.

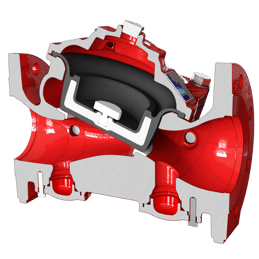

Bermad FP 400Y Torrent® Deluge Valve

To overcome many of the limitations inherent in other valve designs, Bermad recently developed a new addition to their range of FP 400 valve line - the FP 400Y Torrent® Deluge Valve.

To overcome many of the limitations inherent in other valve designs, Bermad recently developed a new addition to their range of FP 400 valve line - the FP 400Y Torrent® Deluge Valve.

The valve supports pressure classes up to 25 bar and conforms to new international standards, including UL and FM.

The FP 400Y is an elastomeric globe valve with no mechanical friction offering extremely high reliability -- a characteristic that is essential in deluge systems. Its innovative design provides full bore linear flow with an uninterrupted flow path, void of any guides, stems or supporting ribs. In it's design, particular attention has been paid to the ease of installment, providing maximum uptime.

A key element of the design is the valve's peripherally supported diaphragm with a rugged metallic disk fused into the heart of the diaphragm during the vulcanization process, combining the strength and long-term sealing capability of a globe radial seal disk and seat with the simplicity of the diaphragm valve.

Other features and benefits of the FP 400Y include:

- No mechanical moving parts, which makes it safer and more reliable

- No maintenance needed for its one-piece, molded and elastomeric diaphragm seal

- In-line serviceable

- Minimal downtime with quick cover release and no trim dismantling required

- Improved flow coefficient

- Conformance to the industrial quarter-turn standard, which enables the valve to interface with any monitoring system

- Suitable for service with sea water and foam concentrate

Bermad’s reputation for product excellence and reliability was built up over decades of providing high quality valves and valve components to the fire protection industry. The company’s deluge valves can be found all over the world in oil and gas, power and petrochemical facilities.

For more information on the Bermad FP 400Y Torrent® Deluge Valve, click here.