In a recent BERMAD webinar, “The Optimal Approach to Irrigation Design” our Global Irrigation Unit Manager, Yiftah Enav presented BERMAD's Design Approach when facing the multiple considerations in project design.

Yiftah chose to start our Webinar Series by presenting basic terminology combined with theoretical rules-of-thumb referring to achieving optimal irrigation uniformity.

He then pointed out the gap between theory and practice, with regard to irrigation uniformity, reviewing some of the in-field conditions that affect or impair irrigation uniformity and suggested practical solutions applying control valves and components for long-term cost savings.

<<Missed the webinar? Watch Now>>

During the webinar, questions regarding the theory and practice of obtaining irrigation uniformity were addressed:

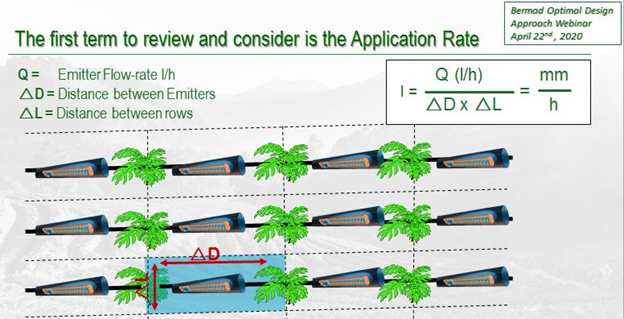

Q: How do you take in account the application rate covers the emitter area if using drip or micros?

A: The application rate is always the flow per soil unit (area) per time. Some emitters "cover" the area above ground while dripper "wetting bulbs" are overlapping under the ground, next to the roots.

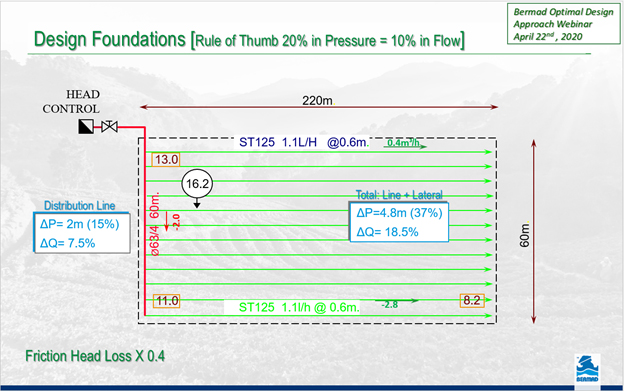

Q: If you use a non-compensating emitter, what's the acceptable pressure & flow window difference to reach high uniformity (over 90%)?

A: The goal is to design a maximum deviation of 10% between the emitter with the highest flow and the one with the lowest flow in the field. On the design map, it is more practical to calculate friction pressure losses, elevations and etc., over emitter flow change per location. This is why we act by the rule of thumb determining that 20% Δ pressure represents ~10% Δ in emitter flow (or any orifice/hole).

BERMAD doesn't design irrigation projects. Our "design office" is the Application Engineering departments and our Sales Engineers team.

We invite our colleagues & customers to approach us as early in the design stage as possible so we can combine our knowledge & experience to improve the design uniformity, reliability and efficiency.

<<Missed the webinar? Watch Now>>

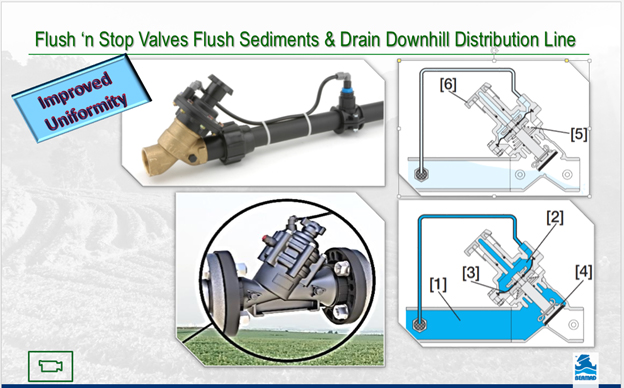

Some questions referred to the Flush 'n-Stop, Double Chamber valve performance, installation and how it contributes to uniformity in different conditions.

Q: At what pressure do the flushing valves open?

A: It is Normally Open and will close as the pressure rises to around 12m. It will reopen when pressure drops back to about 7m. A Flow Stem "M" is a standard feature to allow for pressure "build-up" by manually adjusting (once in a while) the flush flow rate.

Q: What is the recommended distance between valve and inlet of tubing pressure?

A: A couple of meters only to avoid the high flow velocity in the valve area from creating too low dynamic pressure which will prevent the valve closing.

Q: Are Air Valves needed to complete the Flush 'n Stop valve contribution to irrigation uniformity?

A: Kinetic air valve installed at the top of the distribution line will prevent vacuum & suction while shortening line drain time.

See videos of:

Flush 'n Stop valve operating in the field

Combination Air Valve animation

Kinetic Air Valve animation

<<Missed the webinar? Watch Now>>

Q: When using CNL (anti drain) emitters on a 30-50 meter slope downhill design: in addition to installing PRV at the beginning of each lateral, is it better to have Pressure Reducing valves along the subline (somewhere in the middle) or continue using 2" PRV along the line every 10 meters?

A: As CNL emitters are all Pressure Compensating, the designer enjoys wider ΔP "corridor" so depending on the lateral pressure rating, 30m slope should not require additional pressure reducing along the line nor at the beginning of each lateral. Should the slope go further down;,it's better to design a Pressure Reducing valve in the middle of the submain.

BERMAD's Optimal Approach to Irrigation Design

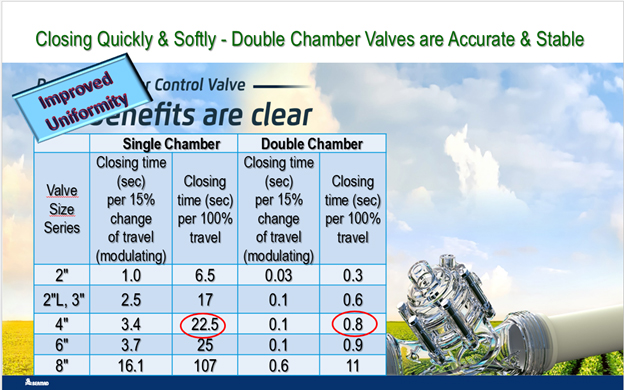

Double Chamber valves attracted lots of interest and many questions relating to the reaction time of valves to close and/or to regulate; size range, pressure rating and operating requirements; and how much more all these benefits cost.

Q: For time of closing, we have a problem with a big valve. Do we need to/can we change the diameter of the Pilots, Solenoid, and Accessories?

A: Usually control accessories can be changed to a certain range, dragging increased cost, cumbersome installation and Non-Standardization. You can remain however with your standard accessories applying them on a Double Chamber valve that closes much faster, providing soft

closure (see table)

Q: I have a Single Chamber valve that takes a while to stabilize at set pressure. Until it stabilizes, it sends the PLC to error on high pressure.

A: Double Chamber valve that closes much faster providing soft closure (see table)

Q: Sometimes in pressure sustaining valves after filtration, we add Galit relay but it still takes more than 1 min for DN>=150 getting it to regulate.

A: Double Chamber valve that closes much faster from fully open to regulate mode (see table)

Q: Is there a PN16 Double Chamber 100 Series?

A: At this stage only PN10. For PN16 & PN 25 we have Double Chamber 700 Series. For PN40, Double Chamber 800 Series

Q: Are there small diameter Double Chamber valves for small plots and pulse irrigation in greenhouses and etc?

A: Double Chamber 100 Series are available at sizes 1½", 2", 2"L, 2½",

and 3". 4" Double Chamber 100 Series is coming soon. For larger diameters up to 24", 700 Series are available.

Q: What is the minimum pressure required for diaphragm to react in Single Chamber and Double Chamber Valves?

A: BERMAD Single Chamber valves will require 3-5 meters to open and operate. Requiring no spring force to close, Double Chamber valves can open and function even at 1-2 meters

Q: What is the cost difference between a single chamber and double chamber valve?

A: At this stage, for Double Chamber 100 Series around 30%

BERMAD Optimal Approach to Irrigation Design

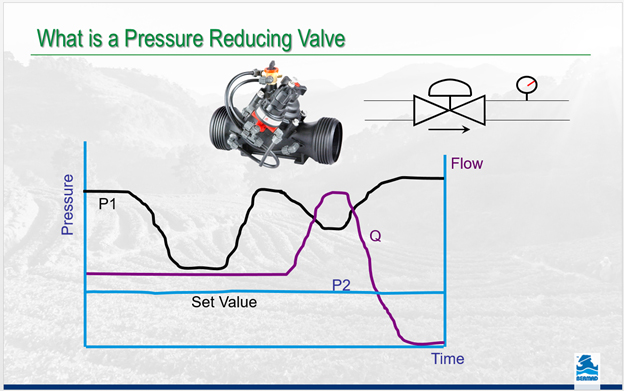

Q: When the flow rate reduces to zero in a PRV, how it is assured that the downstream set pressure is maintained? What operating conditions must be fulfilled to make sure that upstream pressure will not slowly "infiltrate" into the downstream side?

A: When flow rate reduces to zero, momentarily the flow getting into the line through the PRV is greater than the flow out of the line (which is zero). As a result – pressure accumulates and rises in the line, downstream from the PRV. The PRV pilot senses pressure above setting and shuts the PRV, "trying" to reduce pressure back to setting. As the flow is zero (Dead End), even when the valve is drip-tight shut, pressure will not be reduced (assuming no leaks). The definition itself of the PRV is what assures upstream pressure will not slowly "infiltrate" in to the downstream side