In a recent BERMAD webinar, “How to Design & Implement a Pressure Reducing Station for Extreme Pressure Difference,” Nimrod Shafir, our Building & Construction Application Engineer talked about the challenges of designing and implementing water supply systems in high-rise buildings that ensuring reliable water supply and stable pressure to all levels at all times.

During the webinar, questions regarding energy consumption, cavitation ratios and placement of pressure reducing valves (PRV) were addressed:

Q: Is it true that using a PRV will result in high energy consumption? Can you suggest another energy-saving solution?

A: It's true that using a pump to add potential energy to the water and then reducing it is energy is wasteful; it can be described like driving a car a full throttle while controlling the speed with the brakes. Pump manufacturers advise the installation of a VSD pump for each of the pressure zones. While using VSD pumps is an energy saving solution, it’s also a more complex solution than using PRVs which can prove to be a problem at the operation and maintenance stage of the project.

Q: Does a PRV work in static conditions?

A: When there is no consumption and no flow the PRV will tightly close the seal, preventing the high inlet pressure from passing to the downstream.

Q: Is the bottom feed only to reduce the cavitation ratio?

A: Yes, from the point of view of the valve’s position, using a bottom feed is an elegant way to protect it from cavitation or noise problems.

Q: Can we use a piloted PRV as the first stage and another piloted PRV for the second stage, setting them at ratios lower than 2.5:1 to further avoid noise?

A: Using two piloted PRVs one after another is not recommended because there might be oscillation between them. If using the proportional PRV at a ratio of 2.5:1 is not a valid option, try to use a bottom feed design.

Q: Why do they always use the ratio of 2.5:1 in proportional pressure reducing valves instead of a ratio of 3:1?

A: First, the ratio of 3:1 is too close to the condition at which cavitation and noise occurs and we’d like to maintain a gap.

Second, if the overhaul required reduction (on both stages combined) is slightly above 3, then using a proportional PRV with a ratio of 3:1 will not leave the following stage enough pressure to operate.

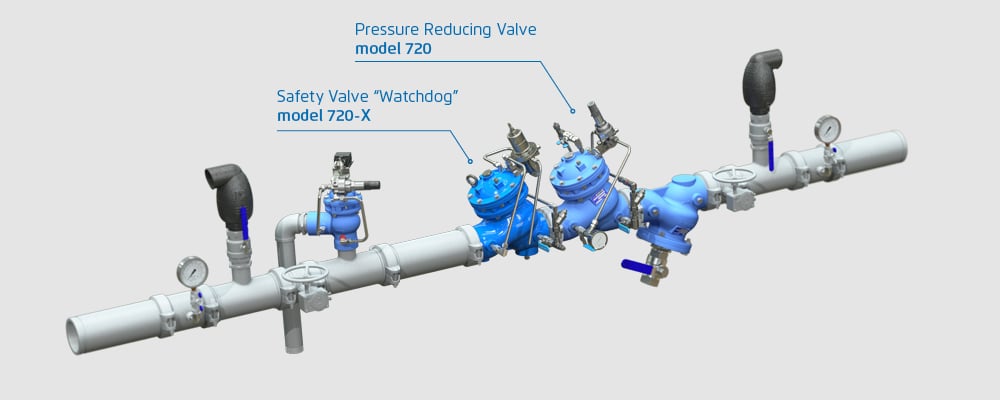

Q: Is any distance required between a proportional PRV and pilot-operated PRV?

A: There is no minimal distance required between the valves. As seen in the photo below, they are connected to each other. This configuration saves much needed space in building installations.

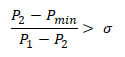

Q: When pressure is reduced from 10 to 4 bar (for example), you have a peak of low pressure. How do we know this value doesn’t exceed the cavitation value?

A: The simple solution is to keep the PRV operating at a ratio below 3:1. The slightly more complex solution is to maintain the value Pmin above the vapor pressure of water (0.02 bar absolute):

Where σ is a value of the valve (in most Globe valve σ≈0.5) and all pressures are absolute.

For more complex calculations, prediction of valve life time under cavitation conditions, and estimation of noise levels, we use our dedicated BERMAD Sizing program.

One of the biggest challenges of designing and implementing water supply systems in high-rise buildings is ensuring reliable water supply and stable pressure to all levels at all times. In this webinar, we will be discussing how to overcome this challenge by efficiently distributing pressure zones in high-rise buildings. In addition, we will be examining different types of pressure reducing systems and valves, and how to install them correctly for optimal results.