Variable flow pumping systems are becoming the preferred HVAC system for new buildings today. And, increasingly, constant volume heating and cooling systems are being converted to the variable flow systems in existing buildings to capitalize on the energy savings they can provide.

However, the savings and the performance of variable flow systems are highly dependent on the ability to control the flow throughout the system. Efficient and effective HVAC circulating fluid systems require flow control solutions that control the flow rates throughout the system in order to properly control and maintain the temperature in all conditioned spaces.

<< Download brochure on BERMAD's Integrated Pressure Reducing System >>

Importance of Flow Control in Systems with Excessive Flow

One common flow-related issue that can occur in HVAC systems is excessive flow in the distribution branches. Excessive flow in a branch means that energy is being diverted to one branch at the expense of another, causing imbalanced distribution of heat control.

Poor flow control impacts the performance of the system in two ways – working outside of equipment efficient design flow and by producing uncomfortable room climate conditions promoting occupants to react by wasting energy.

.jpg?width=1000&name=Solutions%20for%20Flow%20Control%20in%20HVAC%20systems%20(4).jpg)

Balancing flow is critical both in terms of operation and efficiency. A balanced system is one in which fluid flow through each coil in the system is within plus or minus 10 percent of the design flow, providing the correct amount of heat or cooled air. When flow rates are too low, the coils will not condition adequately. When flow over the coils is too high we push more water than needed through the system with accompanying friction losses.

When a system experiences low flows, it may not provide sufficient heating or cooling in all areas leading to occupant complaints. On the other hand, excessive heat or chilling from high flows might induce the occupants to counter the HVAC system, for example by opening a window, which results in wasted energy.

Controlling Flow Means Choosing the Right Valve

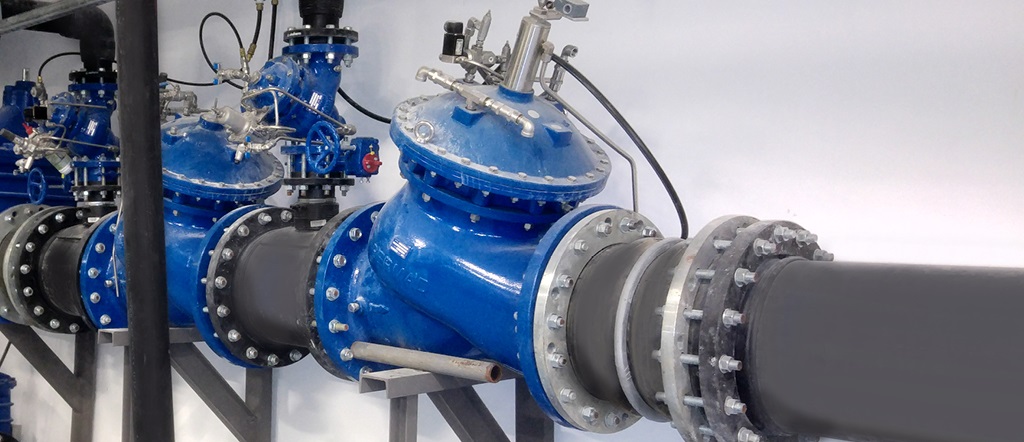

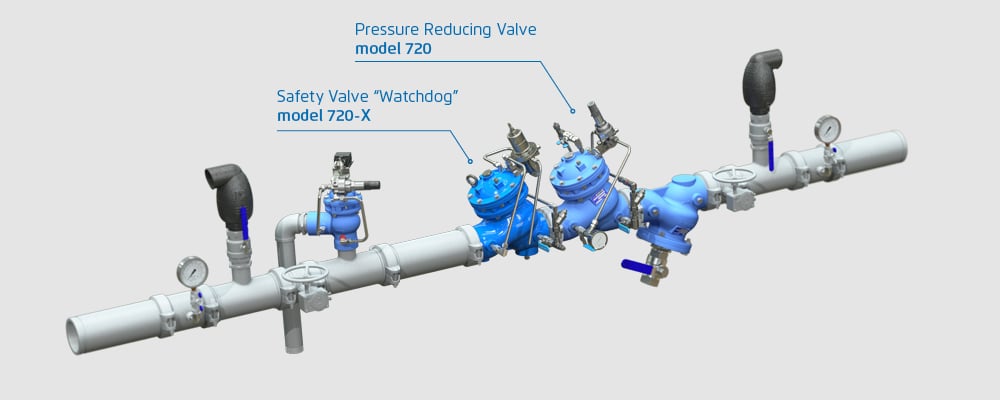

Automatic flow regulating valves help to ensure that each heat exchanger has the correct flow at all times and under all load conditions. BERMAD offers a range of mid-sized to large piloted diaphragm valves that include a smaller pilot valve functioning as a sensing mechanism for the larger main regulator. The pilot valve doesn’t change its calibration in response to flows in the main valve, making the valve pressure independent and improving its overall accuracy.

BERMAD's Model 770-U is a hydraulically operated, diaphragm actuated control valve that maintains pre-set maximum flow, regardless of varying system pressure. These features protect the system from significant deviations from the expected flow range, which can disrupt the supply of fluid to one or more sections of the system resulting in loss of heating and cooling in different sections of a building and can damage system components due to high flows and erosion.

.jpg?width=1000&name=Solutions%20for%20Flow%20Control%20in%20HVAC%20systems%20(2).jpg)

In another scenario, the system might suffer from very low demand if the flow rate falls below the specified minimum design flow. When this happens, the system can get short-circuited causing the chiller to freeze or the boiler to overheat. This scenario could result in a catastrophic failure of the system, underscoring the importance of effective flow control. Given this, two-way valves should include the ability to sustain preset minimal differential pressure between distribution and collection lines safeguarding the system minimum flow to protect the coils and relieve excessive pressure. BERMAD’s 736 Differentiating Pressure Sustaining Valve offers a solution to this problem. Installed as a bypass between the supply and return line, the BERMAD 736 will sense pressure in both lines and open when the pressure differential between them has reached the pre-set high value. This controlled opening of a bypass allows for minimal circulation of water in the system and provides the additional benefit of a fast system start-up.

A different and opposite case can occur when demand is too high. Under these circumstances, low resistance branches might draw most of the flow through them while depleting the flow for other branches. The BERMAD 726 Differentiating Pressure Reducing Valve when installed in line with the fan coil units or heat exchanger, will sense the pressure before and after the heat exchanger and modulate to close when the differential pressure reaches a pre-set low value. This added restriction to the line will ensure flow through low resistant branches is limited so that the other branches are supplying sufficient heat to their consumers.

These are just three of the many valves BERMAD offers for today’s HVAC systems. BERMAD valves are highly reliable, simple to operate, reduce energy costs, and offer additional features that allow customization to meet the needs of any system. To learn more about BERMAD’s HVAC flow control solutions, contact Nimrod today.