In a previous blog post, we described how as a result of rising awareness about energy savings and environment protection, water supply and distribution systems need to be more efficient and be able to operate optimally at minimum pressures. While single-chamber control valves were traditionally used in these systems due to their cost-efficiency, their functionality is limited in such low pressure conditions.

To meet this need, BERMAD developed its 700 SIGMAM series double-chamber control valves, which have a unique design that is only available in the BERMAD 700 SIGMA series, and are the same size as their single-chamber counterparts. They are also the only valves on the market that enable water system designers and owners to easily convert their single-chamber valves into double-chamber valves, and thus optimize their systems for smooth, accurate, secured, stable, and efficient operations under low pressure conditions.

BERMAD 700 SIGMA series double-chamber control valves offer unique features for water supply and distribution systems

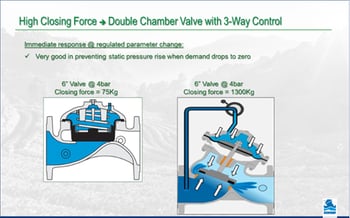

Immediate response and regulating with three-way pilot

In the case of low-pressure conditions in the network, a double-chamber valve with a three-way pilot can completely vent the control chamber, enabling the valve to open fully. This means that the valve is transparent in terms of headloss. In addition, the valve resistance becomes minor and the valve supplies sufficient pressure to consumers without creating a negligible pressure drop.

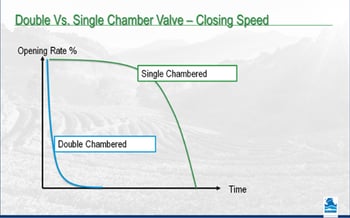

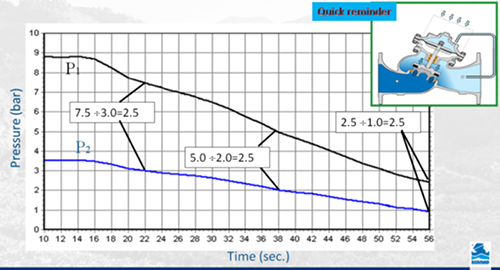

Fast and powerful, smooth non-slam closure without water hammer

In BERMAD 700 SIGMA series double-chamber valves, the diaphragm is isolated from the downstream pressure, which applies the valve opening force in single-chamber valves. When a double-chamber valve is opened, the closing and opening forces on the seal disc neutralize each other. To start the closing process, the upstream pressure water is diverted to the upper control chamber. Since there are no opposing opening forces, the diaphragm assembly and shaft move the seal disc quickly, in a linear direction and with high force, towards the seat.

When the valve is almost closed and head loss is starting to build up, the downstream pressure starts to diminish. The balance of forces on the seal disc changes and the upstream pressure causes the closing process to slow down. As a result, the end of the closing process is smooth and soft. This built-in feature is essential to modern water supply and distribution systems as it protects them against potentially damaging scenarios such as water hammer due to valve closure.

The concept of Clam Networks has become more common and is now widely used in water utilities. This has led to increasing awareness about the slamming of PRVs; and is exactly where non-slam, double-chamber valves offer a vital advantage.

Pilot-less proportional pressure reducing: no pilot, filter, or restriction

In a double-chamber valve, when the lower control chamber is vented to the atmosphere, connecting a control tube from the downstream to the upper control chamber creates a proportional pressure-reducing mechanism that reduces any level of upstream pressure to a lower downstream pressure at a constant ratio.

The pressure reducing is done without the need for a pilot, control water filter, needle valves, or restrictions. Only a "full-bore" control tube is required to achieve an immediate response, absolute stability, and very high reliability.

This feature is unique to BERMAD 700 SIGMA double-chamber valves and is ideal for the following applications:

- Equal divison of erosion and cavitation loads in systems with high differential pressure by installing a proportional PRV upstream from an adjustable pressure reducing, level control, or circulating pressure sustaining valve.

- Reduction of hunting-free down-hill pressure – the stability, reliability, and immediate response prevent hunting and offer an excellent solution for sites with limited accessibility and extreme operational conditions.

WW 720 SIGMA PD proportional pressure reducing

The ideal choice for water supply and distribution system installations and upgrades

To summarize, the BERMAD 700 SIGMA double-chamber valve series offers minimum headloss with 3-way pilot regulation, smooth non-slam closure, and pilot-less proportional pressure reducing. These features make them the ideal choice for new installations and upgrades of water supply and distribution installations.