How Bermad designed, developed and delivered a turnkey water supply solution for the Dead Sea region.

The Dead Sea in Israel is a natural wonder which attracts thousands of tourists every year. It’s one of the saltiest bodies of water in the world — so much so that you can float in it, but you can’t drink from it. As the quality and quantity of potable water sources in the area keeps decreasing, the demand keeps increasing —both from the burgeoning hotel industry as well as from agriculture. The Tzafit regional reservoir facility, located some 60 kilometers from the main Dead Sea resort area with the Judea desert reserve in between, was proposed as an alternative potable water source for the region.

Watch how BERMAD overcame incredible challenges and helped bring water to the lowest place on Earth:

The Challenges

Piping water from the Tzafit regional reservoir came with its own set of complex engineering challenges. The reservoir is located some 60 kilometers from the main Dead Sea resort area with the Judea desert reserve in between. In order to preserve the nature reserve, that pipeline had to be buried underground and could not be accessed for maintenance and repairs.

The 830 meter height difference between the Tzafit regional reservoir and the Dead Sea necessitated a unique solution that could reduce the 83-bar upstream pressure to a 5-bar downstream pressure. The reduction in pressure had to be done in a widely-varying flowrate of 50 to 1200 m3/h and in a very small area.

To carry out this extremely challenging project, the Israeli national water supply company Mekorot needed to find an experienced water solutions company that could create a turnkey solution and solve these major challenges. After careful consideration, Mekorot selected Bermad.

Bermad’s Solution

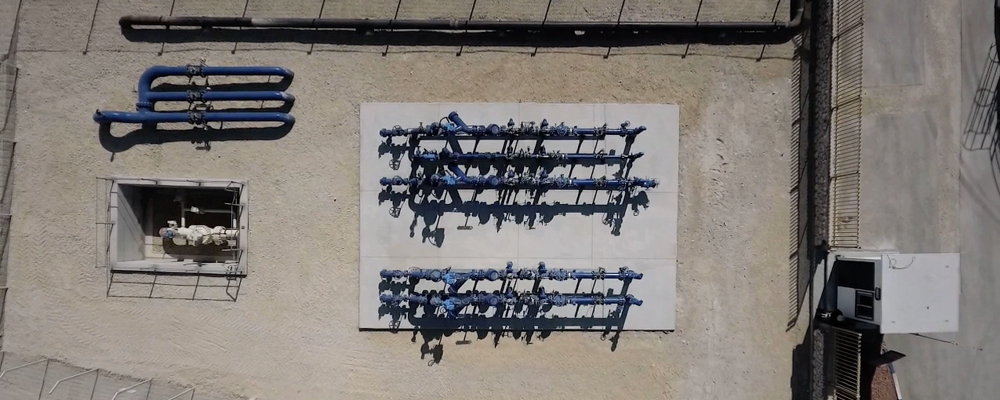

Bermads’s engineers began to design a solution that took multiple design challenges into account, including the remote operation of the station. They had to facilitate the whole range of the required flowrate and to prevent any surges in the 54 kilometers of the marginal scheduled main pipeline, which operates at velocities of up to 2.7 m/s. To overcome this challenge, they divided the pressure reducing station into five parallel branches. The branches have a quick pressure relief valve at the downstream of each pressure reducing stage which also increases redundancy and ensures continuous operation.

The end-to-end project included:

- Sourcing and customizing suitable devices and components including self-operated control valves, stone traps and pressure relief valves for use in high pressure scenarios (PN-100) and also during power failures.

- Designing and implementing a system which:

- Prevents any cavitation damage, vibrations and operation noise levels, which are expected in such pressure regulation ratios.

- Adjusts and monitors the supplied flowrates to the hotels and the Ein Bokek reservoir

- Detects equipment malfunctions, shuts down faulty branches and performs water balance calculations that compare the water supply from the Tzafit reservoir to the amount actually consumed at the hotels.

- Manages changes in inlet pressure by using proportional reducing valves that only function when needed.

- Carrying out all work according to Mekorot’s standards and specifications, and under close supervision including x-ray, ultrasound and interior pipe imaging inspections.

The Results

Bermad designed and implemented the entire project within six months. The system took into account the unique 3-dimensional design of the limited area assigned for the project, while also focusing on safety, as well as easy operation and maintenance.

In May 2017, after comprehensive static and dynamic testing, Bermad handed over the project to Mekorot employees, who also underwent theoretical and onsite hands-on training. The system is now operating successfully and is controlled remotely by the Mekorot Command and Control Center in Beersheva, located 100 km away.