The Sakhalin project is a two-phase, on- and off-shore oil and gas development on Sakhalin Island, Russia, located in the Okhotsk Sea. The project is owned and operated by Exxon Neftegas Limited (ENL). Combined, the Sakhalin phase 1 and 2 reserves contain an estimated 1,200 million barrels of crude oil. The project includes Russia’s first LNG plant, and is expected to contribute billions of dollars to the Russian economy. The first Sakhalin 1 well was drilled in 2003.

Water Hammer Challenge

After construction of Sakhalin-1, a water hammer spike was detected in the firewater system. Hydraulic analysis revealed that the problem was caused by entrapped air at startup of the main, diesel driven vertical turbine pumps creating nearly a millisecond spike of pressure up to 700 psi.

Typically, fire protection systems are designed to a maximum operating pressure of 250 psi. A pressure spike of this magnitude places significant stress on all parts of the system, including pipes, valves, pumps, and other components. This can lead to leaks and premature equipment breakdown as well as safety and environmental hazards.

Anxious to avoid a similar situation in the Sakhalin-2 system, Exxon Neftegas, through Worley Parsons Engineers, contacted BERMAD to determine how they could solve the problem.

The BERMAD Solution

After reviewing the situation and the project requirements, BERMAD engineers concluded that the ideal solution would be to construct a special relief valve.

This valve would be kept in a normally open position, rather than normally closed as in a standard relief valve, which were used before on special occasions only.

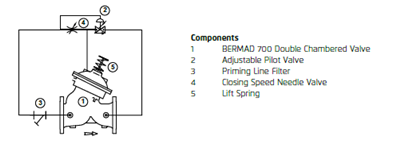

The result was the FS-748-BL-AB Multifunctional Valve. This valve is equipped with a lifting spring and double chamber actuator that enables multi-functional operations. At pump startup, the spring holds it open, allowing all the air to vent from the system. Once the system reaches 1 to 1.5 bar of pressure, the valve closes and enters its pressure control operational setting. During operation it operates as a normal fire-pump relief valve.

The result was the FS-748-BL-AB Multifunctional Valve. This valve is equipped with a lifting spring and double chamber actuator that enables multi-functional operations. At pump startup, the spring holds it open, allowing all the air to vent from the system. Once the system reaches 1 to 1.5 bar of pressure, the valve closes and enters its pressure control operational setting. During operation it operates as a normal fire-pump relief valve.

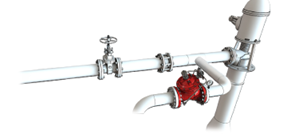

All three diesel driven, vertical turbine, main fire pumps for the Sakhalin-2 project were subsequently equipped with 10” nickel aluminium bronze FS-748-BL-AB Multifunctional Valves, with Monel tubing and fittings for superior corrosion resistance. BERMAD also provided all operating and maintenance manuals for the new valve in both English and Russian versions per client request.

Results

The 748 Multifunctional Valves successfully prevented high capacity fire pump water surge issues at Sakhalin-2, thus preventing damage and ensuring optimal safety and longevity of the fire protection system.

The 748 Multifunctional Valves successfully prevented high capacity fire pump water surge issues at Sakhalin-2, thus preventing damage and ensuring optimal safety and longevity of the fire protection system.

Since then, the valve has been used in several other fire protection systems. One of these is ExxonMobil’s offshore Hebron field in the North Atlantic, for which BERMAD supplied over a dozen 748 valves containing special materials, including super duplex stainless steel.

The 748 has been updated to the 730-48 valve, and is on its way to becoming a preferred choice for water hammer protection in fire protection systems utilizing vertical turbine fire pumps. Its invention is an excellent example of BERMAD’s commitment to creating innovative and effective fire protection solutions in response to client need.