In a recent BERMAD webinar, “Air Control in Sewage & Wastewater Applications,” Eyal Geller, our Air Valves Product Manager, shared some insights regarding the use of air valves in sewage and wastewater applications.

<<Missed the webinar? Watch Now>>

During the webinar, questions regarding the usage of air valves in sewage & wastewater systems and considerations for air valve selection, installation, operation & maintenance, were addressed:

Q: What considerations need to be taken into account when using air valves in sewage and wastewater systems?

A: Air valves are important for efficient operation during pipeline filling and pressurized operation as well as protection from vacuum conditions during draining or water hammer and surge pressure scenarios. They are installed at pumping stations, along pressurized collection pipelines, and in the wastewater treatment plants. Air valves installed in sewage and wastewater applications have to cope with grease, fats as well as suspended & dissolved solids or other foreign objects that found their way into the sewage system. Since sewage and wastewater air valves are engineered products, their selection should be based on parameters such as performance, size and their positions in the system

<<Missed the webinar? Watch Now>>

Q: How can I select the right air valve for optimal performance?

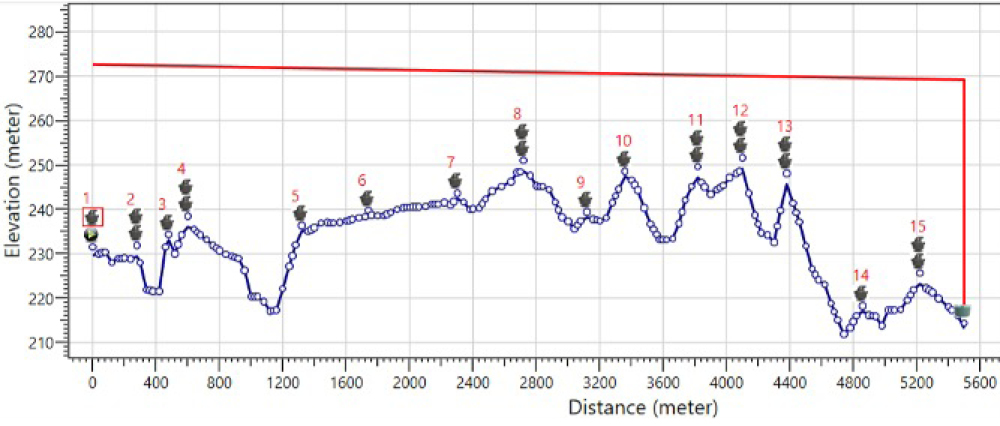

A: BERMAD’s application engineering approach is to evaluate the volume of air which needs to be controlled and then to select the air valves which comply with the required air flow capacity. To ensure design optimization, valve selection should be undertaken using common formulas or specialized software such as BERMAD AIR. In some cases, recommendations from surge analysis software must be used. While a rule of thumb can be used to estimate the preliminary estimation, it cannot replace the above approach. In addition to common specifications for air valve (type, construction, pressure rating and inlet connection) it is important to specify the required air flow capacity. This will ensure that the installed air valve has an air flow capacity that complies with design.

BERMAD AIR – Air Valve's sizing and positioning software

Q: Are air valves required for a sewage collection gravity line?

A: Air valves are not required in gravity systems where the pipeline isn’t pressurized i.e. flow at semi-cross section (such as in a tunnel). These type of unpressurised gravity lines are typical for the beginning of the domestic sewage network, which collects the fluid from the households to a midway pumping station/tank. In gravity lines where the pipeline is pressurized e.g. delivering sewage from a mountain to treatment plant located in the valley, air valves do need to be considered. One of the common objectives in such systems is to prevent vacuum conditions during draining.

Q: What is the recommended distance between air valves in horizontal pipelines?

A: Combination air valves should be considered at the beginning and end of long horizontal sections, and automatic air valve (or combination) should be considered at intervals of 1/4-1/2 mile; 400-800m along horizontal sections of pipelines.

Q: Does BERMAD offer support during the design process?

A: BERMAD’s application engineers are at your service for engineering reviews of project designs and operations. They will support you in defining the air control requirements and will provide engineering recommendations, based on sizing & positioning and surge analysis software.

Q: What considerations need to be taken for installation, operation and maintenance?

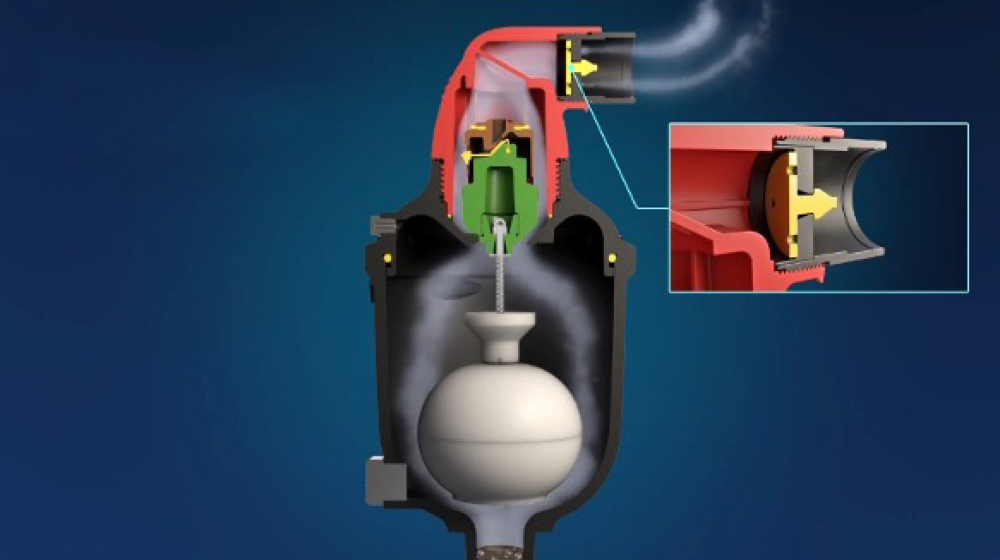

A: When connecting an air valve to a drainage pipeline, it is important to use a drainage pipe line which has the same diameter as the valve outlet. The surge protection feature is recommended to cope with risks for surge pressures, caused by pump operation by pulses (sometimes several cycles of start-up and shut off during one hour). It will also contribute to preventing grease and solids from reaching the upper mechanism. Since the system pressure is relatively low and the pipeline is flat, an air valve with low pressure sealing of 0.8 psi; 0.05 bar will prevent leakage. It’s important to look for air valves that are easy to maintain – lightweight, top opening enabling the internal assembly to be pulled up for quick replacement, back flush option and 100% corrosion resistance. Following these guidelines will facilitate longer periods of maintenance-free operation and reduce costs.

Cutaway of BERMAD C50 with Surge Protection feature

BERMAD C50 can be opened from the top, enabling the internal assembly to be pulled up for quick replacement or service

Q: Some sewage valves cause splashing during closure. How does BERMAD’s valve perform during closure?

A: BERMAD’s C50 was designed to prevent water spitting at the end of pump start up or during automatic air release. In addition, the valve’s low-pressure sealing is 0.05 bar which helps to prevent leakage.

Watch the animation of BERMAD C50 principles of operation

Q: To avoid clogging of air valves, should strainers be installed?

A: A strainer connected beneath the air valve inlet can also get clogged. In addition, the strainer will limit the air flow capacity. Best to select an air valve able to cope with the suspended solids, grease and fats.