Cavitation, which can damage delivery networks, is a given in all water supply systems. However, it is a particular concern in Australia where water supplies are already limited. In systems with inadequate pressure controls, cavitation can lead to significant damage, including pipe bursts, and ultimately a pipe burst if pressure is not properly controlled.

The Challenge

Cavitation was a top concern for one municipal water authority in Southern Australia as it sought to develop an alternative source of water to meet the demands of a growing population. The utility was already serving more than a million people and needed a new pipeline to serve as a backup. With such a large system, maintaining the proper pressure to ensure the delivery of water throughout the entire network was difficult.

In a system with such widely varying pressure, the cavitation it can cause would made the addition of a new pipeline risky business and the selection of a valve to control it of paramount importance. So, the utility turned to BERMAD for a solution – a valve that would work reliably without cavitation to ensure the safety and stability of its pipeline.

The Solution

BERMAD understood the critical nature of the situation. With more than a million people relying on the utility for their water supplies, valve failure would could be catastrophic to the downstream reticulation network.

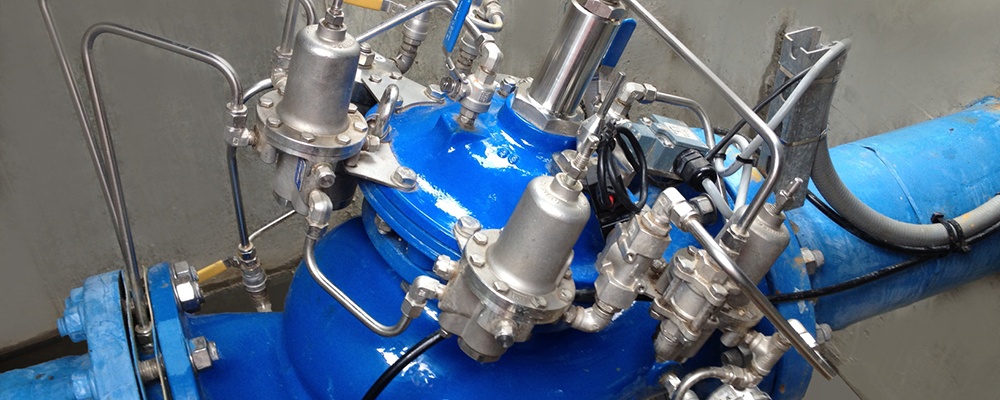

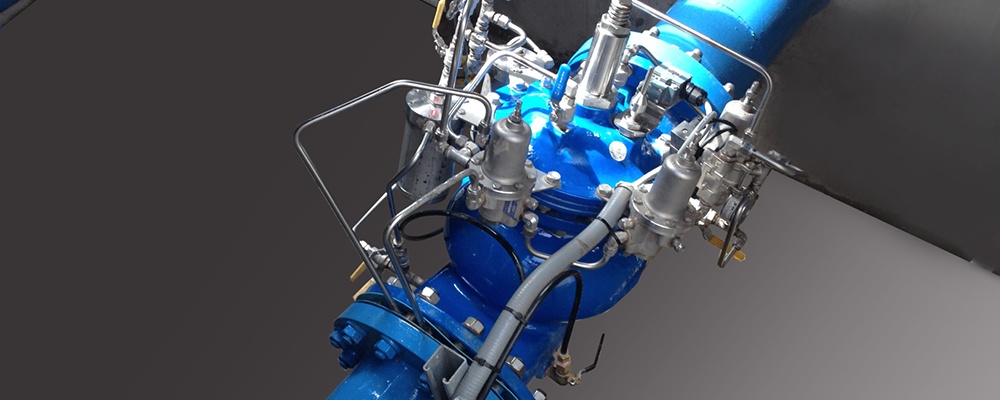

BERMAD worked with the utility and its design engineers to install a 700 SIGMA Series valve, which is highly resistant to cavitation and explored additional safeguards available to ensure the valve would protect the pipeline and function well in the widely varying pressure conditions they faced.

Read more about how BERMAD Australia supported the utility throughout all stages of the project, from solution design through to implementation and after-sale support.