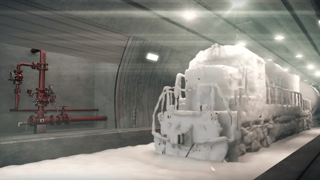

Thankfully, tunnel fires don’t happen very often. But when they do, they can be catastrophic.

Fires can occur inside a tunnel, or be brought into the tunnel by a vehicle (for instance, due to friction, faulty electrical connections, or spontaneous combustion of cargo.) Tunnels are also sensitive to terrorist sabotage. Both roadway tunnels and train tunnels present the ideal conditions for a fire to get dangerously out of hand:

- It is not uncommon for ambient temperatures inside a tunnel to get as high as 30˚-40˚ C (86˚ - 104˚ F), even when there is snow outside.

- Wind flowing through a tunnel can quickly spread a fire once it is started.

- The constricted space inside a tunnel creates ideal conditions for the concentration of smoke and hazardous gases.

- Escape and rescue from a tunnel inferno is typically dangerous and difficult.

Fire is always a dangerous scenario. But when it occurs inside a tunnel, the risk is multiplied—especially in cases where flammable substances are being transported through the tunnel. A train or car full of fuel, once ignited, can create an explosion powerful enough to melt the car itself and send objects and molten metal flying out the tunnel’s mouth and ventilation shafts.

Even in less dramatic cases, a tunnel blaze can destroy not only vehicles and cargo, but costly infrastructure such as concrete, train track, lighting systems, electrical cables, refrigeration pipe, and signaling equipment—not to mention tragic loss of human health and life.

Most tunnels are not protected against fire scenarios. However, equipping a tunnel with a proper fire protecting system is a smart investment that can prevent tragedy before it happens. BERMAD’S family of fire protection deluge valves play a critical role in tunnel fire protection and control.

How Tunnel Fire Protection Works

A tunnel fire protection system can effectively sense and put out tunnel fires before they get out of hand. Here’s how:

- Detection: Sensors installed along the tunnel detect the presence of heat and/or flame.

- Alarm: Once the sensors detect the presence of a fire, they immediately trigger an alarm to sound, alerting anyone in the area to the danger so they can seek safety, take action against the fire, and/or call for help.

- Valve engagement: As they sound the alarm, the sensors also send an electric signal to the system’s control panel, which then triggers the specific deluge valves positioned near the fire to open.

- Extinguishing fire: The fire protection valves release foam into the tunnel fire location, extinguishing the flame and averting potential disaster.

- Reset: Normally, fire protection valves are reset manually after an incident. However, in a tunnel situation they are designed to be reset remotely in order to avoid exposing human workers to the high heat and risk a post-fire scenario.

What to Look for in a Deluge Valve for Tunnel Fire Protection

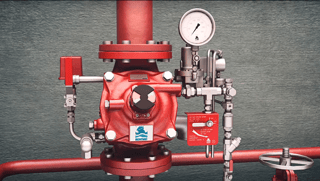

Deluge valves are used in situations (like tunnel fires) where it is desirable to spray from all open sprinklers while the system is operating. Tunnel fire protection calls for several specific qualities one should look for when selecting deluge valves:

- Durability: Due to the limited accessibility inside a tunnel, these valves often are called to endure long periods of pressurization without inspection or service.

- Reliability: Alternate forms of fire protection are not easily engaged in a tunnel fire situation. It’s critical that valves perform instantly and as expected.

- Pressure control: When there is flow in the system (as occurs when valves are triggered), pressure can vary depending on the valve’s location inside the tunnel, especially in a long pipeline, performance limiting head loss can occur at high flows, so pressure balancing across the whole system becomes imperative for an equal and optimal delivery of the extinguishing media through the whole length of the tunnel, so it is important that the valve be able to automatically adjust the pressure to avoid underperformance.

- Low head loss: A valve that functions with a low head loss or friction loss is always desirable in fire protection systems that might experience lack of pressure during a fire event.

- In-line serviceable: It’s important for tunnel fire prevention valves to be serviceable without having to remove them from the line. This is both safer and faster, minimizing the duration of in-tunnel service visits and avoiding unnecessary downtime to the system.

- Diaphragm type valve: For tunnel applications, look for a diaphragm-type deluge valve that is both pressure controlling and self-actuating. This is the only design that can perform properly in this situation.

BERMAD Deluge Valves for Tunnel Fire Protection

BERMAD’s 400Y and 400E deluge valves are ideal for use in a tunnel fire protection system.

BERMAD’s 400Y and 400E deluge valves are ideal for use in a tunnel fire protection system.

Highly durable and reliable, these elastomeric- type globe valves are rolling-diaphragm actuated, with an integral, solid, resilient seal. The valve assemblies are engineered for resilience, drip-tight sealing, long-life, and controlled actuation, even under harsh conditions.

The unique hydro-dynamic globe design of our 400 series valves provides high flow capabilities with minimum head loss. Covers are removable for quick in-line inspection and servicing; the elastomeric assembly can be easily removed from the valve body with no need for disassembling the valve from the line.

Designed for vertical or horizontal installation, BERMAD 400 series valves are available in diameter sizes from 1½” to 16”. Like all BERMAD products, they are fully supported by our experienced and knowledgeable service team.