Air valves are essential for air control in water systems. They help prevent inefficiency caused by air that is trapped during filling and pressurized operation, as well as to prevent damage in vacuum conditions and pressure surges.

However, air valves are known to leak, especially when located at low pressure points in the water system. This can cause water wastage and interrupt the smooth operation of the water system.

Reasons for Air Valve Leakage

The following are common reasons for air valve leakage:

- Insufficient operating pressure. Low pressure conditions occur at high points, at the end of the pipeline or at the pump shut off. Common air valves with a minimal operating pressure of 0.2-0.5 bar; 3-7.5 psi will not sufficiently seal at low-pressure conditions, thus causing potential water wastage and interference with operation. In order to solve this, system designers tend to increase water pressure in the system and/or raise the air valve installation points. These solutions are inefficient in terms of system overall cost and operational needs.

- Poor water quality. Foreign particles and dirt present in the water supply tend to interfere with air valve seals, and this then leads to leaking valves. This issue can be addressed through periodic maintenance and cleaning.

Selecting Air Valves Designed for Low Pressure and Reduced Leakage

As with all engineered products, water system designers and operators need to consider the air valves selected for the system, as well as their functionality – making proper valve selection critical.

An air valve with low pressure sealing will function appropriately within a system designed for optimal energy and water efficiency. Air valves designed for minimal maintenance will likewise save the time and costs involved in performing periodic maintenance, and will also reduce system downtime.

The C70 Combination Air Valve: Designed for Low Pressure Sealing and Low Maintenance

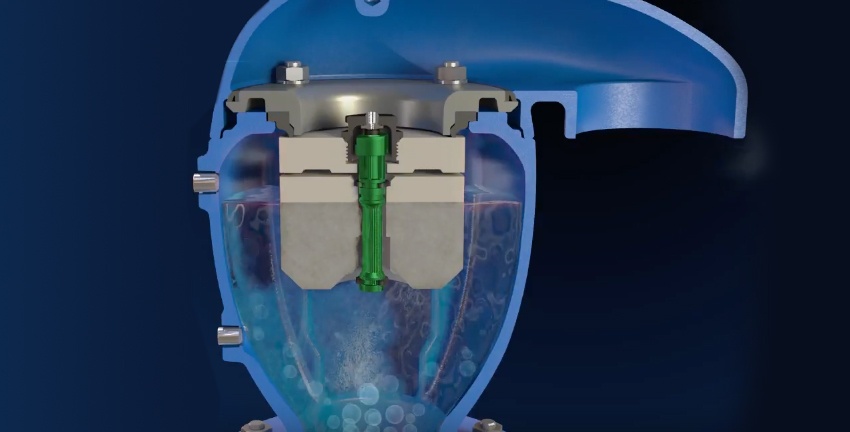

The BERMAD C70 combination air valve is a high-quality valve suitable for a variety of water networks and operating conditions. The C70 efficiently and effectively evacuates air during pipeline filling, and releases air pockets from pressurized pipes during operation. This air valve also enables large volume air intake to prevent vacuum conditions during network draining. The C70 is specifically designed to address the two major causes of leaky air valves.

The resulting air valve offers exceptional performance in a number of areas, including higher flow rates, and an anti-slam feature for built-in surge protection. However, it is especially noted for its superior leakage prevention. This is because of its low pressure sealing design, which allows it to operate flawlessly at a minimal operating pressure of 0.1 bar;1.5 psi. It is therefore a suitable choice for locating at low pressure points in a water system without the need to increase operating pressure or raise installation points.

This valve features a compact, simple, robust structure with completely corrosion-resistant internal parts. In order to prevent leakage as a result of dirt or foreign bodies, the C70 valve has a unique patent-pending mechanism that separates the fluid from the seals. This allows it to work with water of varying quality, including effluent, with fewer maintenance problems than most other combination air valves on the market. . In addition, the valve is designed to be easy to install and service in a variety of site conditions.

Exceptional Value in a Long-Lived Valve

The BERMAD C70 combination air valve offers exceptional value for the water system designer seeking a low maintenance, leak free solution in a valve capable of operating at lower-than-normal water system operating pressure. Its low pressure sealing features and robust design result in a long-lived valve that is cost-effective to operate.

Click here to learn more about the BERMAD C70 combination air valve, or contact us here to locate a BERMAD representative in your region.