Water surge or water hammer is a pressure wave in a piping system caused when a fluid in motion is forced to stop or change velocity or direction suddenly. Pressure surges in fire water systems can be caused by a number of different factors, such as a valve closing or opening too quickly or a pump starting or shutting down suddenly. This momentum change can create a significant and potentially damaging pressure rise.

Most fire protection systems are designed to operate at a maximum working pressure of 12 barg (175 psi). Pressure waves from water hammer or pressure surge can easily exceed 50 barg (740 psi), thus creating a very real threat of damage to piping and instrumentation.

The pictures below show two examples of catastrophic damage to piping and accessories caused by water surge/water hammer in fire protection systems.

<< Download our white paper to learn more about

preventing water hammer in fire protection systems >>

A valve casing cracked by surge pressure, Piping breached by water hammer.

A valve casing cracked by surge pressure, Piping breached by water hammer.

5 Ways to Prevent Water Pressure Surge in Fire Protection Systems

There are a number of different methods that can be employed to lessen or prevent pressure surges. The following five solutions present some favored approaches to addressing water surge or hammer problems.

1. Anti-Surge Pump Control Valve

An effective way to prevent surge or water hammer deriving from the start-up of Vertical Shaft Turbine Pumps is to use a normally open pre-emptive adjustable relief valve such as the BERMAD model FP-730-48-BL to prevent the pump start surge wave at the source.

As it is a normally open valve, it will efficiently relieve any air and surge potential on pump start-up. As soon as pump pressure below the set maximum arrives at the valve inlet, the valve will close and continue to work as a relief valve.

2. Anti-Surge Fire Pump Control and Check Valve

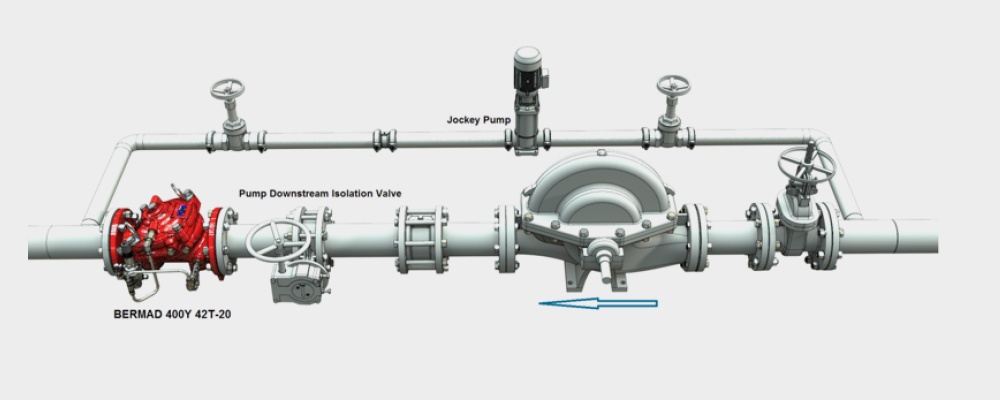

When the pump start-up momentarily creates an intolerable surge level, a Fire Pump Control valve suitable for most pump configurations presents an efficient all-round solution.

When the fire pump is dormant this valve will be held closed using the system jockey pump pressure. When the pump starts the initial surge will be prevented by the closed valve that will continue to open, releasing water into the system in a controlled manner preventing any surge or water hammer.

A good example of such a valve is the UL listed BERMAD 42T-20. When needed this valve can double/triple up to be used as a pressure control valve and a check valve whilst simultaneously preventing surge or water hammer damage at pump start up.

3. Valve Closing or Opening Speed Control

Water hammer can be caused by overly fast reaction of fire protection valves. Most fire protection systems take into consideration the aggressive nature of fire protection water flow, designed to get the extinguishing media to the application devices in the shortest time possible. Despite this, there is occasionally a need for valve reaction control when the level of surge pressure is intolerable and piping and instruments must be protected.

Certain valves can be equipped with a reaction speed device to control the rate of opening and/or closing to avoid damaging surge. This way, we can control the valve’s closing and/or opening speed as required, and soften the surge effect to a bearable level.

4. Jockey Pump Pressure

For a variety of reasons, the jockey pump or maintenance pressure can often be set substantially lower than that of the system's operation pressure, so when a pump starts in a pressurized fire protection system, it has to raise the pressure held in the system by the jockey pump up to the system operating pressure. This always creates some form of surge, sometimes the surge level can be damaging.

By reducing the difference between the jockey pump start pressure and the fire pump operational pressure, we can reduce the surge to a manageable level. For example, when the operating pressure is 12 barg and the system maintenance pressure or jockey pump pressure is 6 barg the main pump will have to quickly raise the pressure at least 6 bar with a resultant initial surge on main pump start- up. Setting the maintenance pressure closer to the operation pressure will effectively lessen the surge. The less the pressure difference the less will be the surge.

5. Anti-Surge Bladder Tanks

An effective answer to existing water surge or hammer is a surge preventing bladder tank that can be installed on the pipeline. The steel tank contains a flexible bladder which is fixed to the tank’s connection with the main pipe of the water system. The bladder shape is similar to the tank’s shape, so it can expand to the full capacity of the tank. Compressed air is confined between the bladder and the external tank’s housing at a pressure level compatible with system requirements. The bladder’s internal and external pressures are always equal, enabling inbound and outbound flows of water as needed.

On arrival of a pressure wave to the bladder tank, the tank will displace the bladder and in effect increase the volume of the system piping to which the surge is delivered. Flow to the expanded area thereby absorbs and suppresses the surge wave.