Fire pumps are used to supply fire protection systems with pressurized water to ensure the smooth operation of the system's extinguishing devices. Because the fire pump's performance has a direct impact on the performance of the entire system, it is crucial to ensure it is functioning correctly.

<< Get the white paper on how to deal with water pressure surge in Fire Protection Systems >>

Most Authorities Having Jurisdiction and the NFPA 25: Standard for the Inspection, Testing, and Maintenance of Water-Based Fire protection, recommend weekly "no flow" or "churn tests," requiring the pump to be fully operational at a no flow condition for 10 or up to 30 minutes, depending on the pump type.

The challenge

A fire pump is a mechanical device used to transform a chosen potential energy source whether it is electric or diesel fuel to kinetic energy in the form of flowing water. By closing the pump outlet valve (during a no-flow or churn test), we deprive the pump of its originally designed purpose of transforming this energy into the kinetic form of flowing water into the system piping. This energy then has to find an alternative transient. At this point, the only alternative for this energy is to transform into static pressure and localized heat created by the friction of the water as it churns around in the pump casing. Excessive heat in the pump can cause severe damage in a short period of time causing pump bearings to fail - as the bearings' lubricants typically degrade twice as fast for each 10 degrees Celsius rise in temperature - while seals and packing begin to leak. In more extreme cases, the rise in temperature can cause the water to flash to vapor and cause cavitation damage to the impeller and pump internals.

The solution

To avoid this damage, we must lower the temperature of the water being churned in the pump casing or housing. This can be achieved by allowing a small amount of cooler water into the pump casing.

To avoid this damage, we must lower the temperature of the water being churned in the pump casing or housing. This can be achieved by allowing a small amount of cooler water into the pump casing.

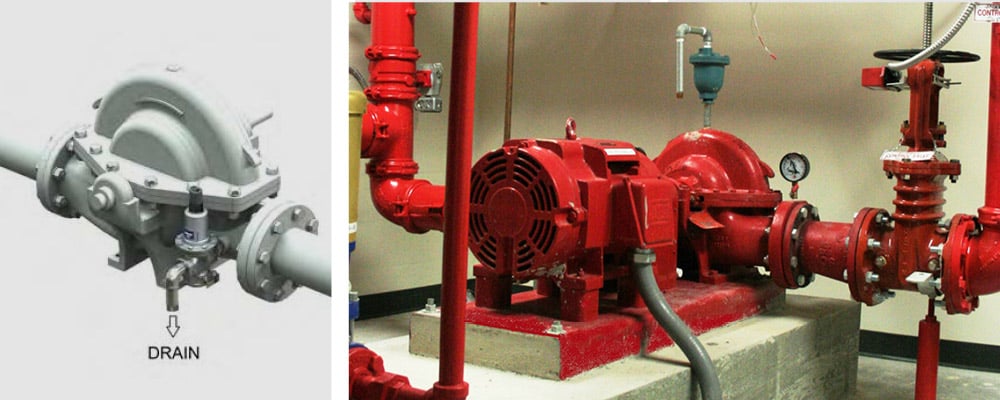

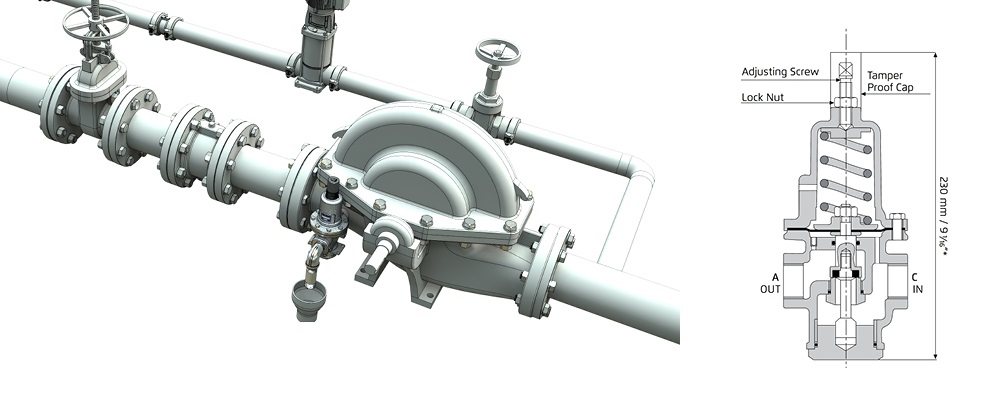

For all fire pump systems, except those using a cooling line to a diesel engine driven pump, a circulation relief valve should be fitted in order to extract heated water from the pump's discharge. This valve should be fitted between the pump discharge side and the outlet control valve. This circulation relief valve should be set to open at the pump unit shutoff pressure plus the minimum pump suction pressure. It should allow a relatively small amount of hot water to constantly flow out of the pump casing, which is then replaced by an equal amount of cool unheated water entering the pump through the suction side, thus cooling the pump and its casing.

Fortunately, water has an exceptionally high "Specific Heat Capacity" in comparison to other commonly found materials, giving it an exceptional cooling ability. This means that only a relatively small amount of water has to be circulated or discharged to ensure that the temperature does not rise to damaging levels.

Things to keep in mind when installing a circulation relief valve

When installing a circulation or casing relief valve, make sure that there is adequate drainage to accommodate the discharge without restricting it. Be sure that the drain itself can handle such amounts of water to prevent the flooding the pump house floor. Equally important is to have an air gap near the drain where the flow from the relief valve can be easily verified by sight from the pump operating position. It is also recommended to occasionally feel the temperature of the water being discharged from the relief valve to determine if the discharge flow is sufficient. The water should be warm but not hot.

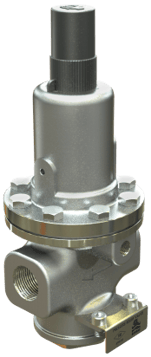

The BERMAD FP 3HC-0 FM approved direct-acting relief valve

The BERMAD FP 3HC-0 FM approved direct-acting relief valve offers an ideal high-quality solution for fire pump circulation applications. It is available in a wide variety of corrosion proof materials to suit all media and environmental conditions. The robust design of this valve ensures a long and reliable service life.

To find out more about our circulation relief valves and other fire-protection products visit our website.