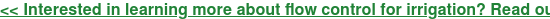

When we need to limit the flow using hydraulic methods (as opposed to electronic methods), the flow is not continuously measured & sampled (only during setting). Therefore, pilots are designed to hydraulically sense the differential of pressure or force/velocity associated with the varying flow.

In most cases, downstream pressure varies due to the use of different irrigation methods, changing demand, unequal irrigation shifts, etc. In these cases, pilots must be designed to continually measure the differential pressure or force/velocity using an upstream Orifice Assy as a flow sensor and differential pressure pilot that continuously sense the actual flow in values of ΔP (connected by two sensing tubes). Pilots such as the Paddle Pilot (PC70) continuously sense the flow in values of ΔF (created by ΔV) on the paddle front versus the back sides.

In special cases, the downstream pressure is constant, for example, in reservoir filling applications where the reservoir level is actually the downstream pressure. In these cases, the method of "PRV to Orifice" can be used because the constant downstream pressure (after the orifice) enables us to sense and control the Orifice upstream pressure by means of a standard pressure reducing pilot and a downstream orifice.

Flow Control Valves in Center Pivot Applications

Flow control valves maintain constant pre-set maximum flow regardless of fluctuating demand or varying system pressure. Interested in learning more about flow control for irrigation?