Water is the most efficient, cheapest and most readily available medium for extinguishing fires of a general nature. It is used by the Fire Service in one form or another in the majority of fire protection situations.

For fire water to do its job successfully, it must be supplied

with the necessary pressure and flow. For this, a fire pump is required most of the time. Many systems also call for pressure regulating equipment, including Pressure Relief Valves and Pressure Control Valves. Standards such as NPFA 20 include requirements concerning pumps and other pressure-related fire protection equipment.

Designing a fire protection system with Pressure Relief and Control Valves requires a great deal of expertise. It is critical for designers to maintain rigid adherence to stringent fire protection guidelines and regulations (including NFPA, government and insurance requirements), in order to avoid mistakes such as using a relief valve to control pressure in a fire protection header.

Let’s take a closer look at specific NFPA guidelines for these fire water pressure regulation valves.

NFPA 20 Compliance for Pressure Relief Valves (PRV)

A Pressure Relief Valve is defined by NFPA 20 (3.3.67.5 Relief Valve) as “A device that allows the diversion of liquid to limit excess pressure in a system.”

In general, a PRV is a safety device, designed to protect a pressurized system during an overpressured event. An overpressured event refers to any condition which would cause pressure in a system to increase beyond the specified design pressure or maximum allowable working pressure. Since Pressure Relief Valves are safety devices, there are many codes and standards written to control their design and application.

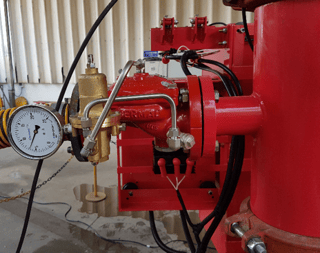

For Centrifugal Pumps, the NFPA 20 (4.19.1.2) requires that “a Pressure Relief Valve shall be installed. where a diesel engine fire pump is installed and where a total of 121 percent of the net rated shutoff (churn) pressure plus the maximum static suction pressure, adjusted for elevation, exceeds the pressure for which the system components are rated.”

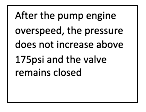

A Pressure Relief Valve is required by the standard to be installed when the diesel engine is turning faster than normal, because the pressure is proportional to the square of the speed that the pump is turned. This is a relatively rare event; if pumps create pressures less than the pressure rating of the fire protection system components [typically 175 psi (12.1 bar)] at 110 percent of rated speed, a Pressure Relief Valve is not required.

Figure 01 – Diesel Fire Pump

Figure 02 – Pressure Relief Valve from BERMAD

The standard specifically does not permit the use of a main pressure relief valve on an electric fire pump, except where a variable speed driver is used. Variable speed drivers are required to default to constant rated speed operation. In the event the variable speed driver fails, the rated speed can result in system over-pressurization. In this case a pressure relief valve is required.

When designing a fire pump, it is highly important that the designer match the pump to the system demands, in order to avoid overpressurizing the system and then using pressure regulating devices to compensate.

NFPA 20 Compliance for Pressure Control Valves (PCV)

Another important piece of equipment aimed to guarantee sufficient flow and pressure water during a fire event is the Pressure Control Valve (PCV).

A Pressure Control Valve is defined by the NFPA 20 (3.3.67.3) [14,2013] as “a pilot-operated pressure-reducing valve designed for the purpose of reducing the downstream water pressure to a specific value under both flowing (residual) and non-flowing (static) conditions.“

Suction Pressure Regulating Valves that are listed for fire pump service are permitted for use in cases where the authority requires positive pressure to be maintained on the suction piping. These valves should be installed according to manufacturers’ recommendations in the piping between the pump and the discharge check valve.

Other Fire Protection Compliance Standards for Pressure Regulating Valves

Other pressure control devices, including PCVs installed downstream of the discharge isolation valve, are beyond the scope of NFPA 20. When permitted by the fire protection authority, they should be installed in accordance with the appropriate listing and installation standard, such as NFPA 13 or NFPA 14.

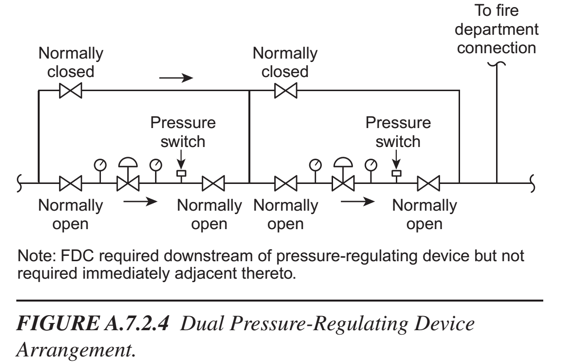

NFPA 14 specifies the condition for using pressure regulating valves, and defines the maximum pressure at hose connection due to the different pressure limitations established. Where the static pressure at a 2½ in. (65 mm) hose connection exceeds 175 psi (12.1 bar), an approved pressure-regulating device shall be provided, to limit static and residual pressures at the outlet of the hose connection to 175 psi (12.1 bar) (7.2.3.2*). It may be necessary to arrange piping so that separate pressure-regulating devices can be provided on Class I and Class II hose connections.

The figure below demonstrates compliance with all requirements:

Need Fire Protection Design Assistance?

BERMAD engineers are available to provide you with expert guidance in fire protection applications and systems. To learn more, click here to contact a BERMAD representative in your region.