A fire event can cause untold damage to property. But sometimes the extinguishing water can do as much damage to protected items as the fire itself. This includes such places as computer rooms, film archives, museums and other moisture-sensitive areas. In such areas where a false alarm can be catastrophic and the deployment of water should be restricted to the fire area alone, rather than the whole building or room, it can make sense to use a preaction fire protection system.

What is a pre-action system?

NFPA 13 - "A sprinkler system employing automatic sprinklers that are attached to a piping system that contains air that might or might not be under pressure, with a supplemental detection system installed in the same areas as the sprinklers"

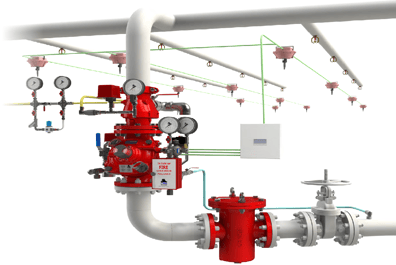

In a pre-action sprinkler system there will normally be supplementary detection devices and closed automatic heat sensitive sprinklers fixed to the air or nitrogen filled system piping in the protected area.

An advantage of closed automatic heat sensitive sprinklers used in pre-action systems is that when opened by a localized heat source, they will only let water into the area where the fire is. This avoids soaking large areas of the protected area as might be with a deluge system and the water damage is typically restricted to the area of the fire only.

Pre-action sprinkler systems keep the piping in the protected area dry. Instead of water, the sprinkler piping is filled with air or nitrogen. This makes some pre-action systems the system of choice for protecting freezing areas such as refrigeration installations.

Different pre-action systems employ different regimens in the activation of the main valve and release of water into the protected area through the sprinklers. The choice of pre-action system depends on the designer's priorities regarding the level or type of protection needed.

Types of pre-action systems

There are three types of preaction system:

Double interlock pre-action

NFPA 13 "Admits water to sprinkler piping upon operation of both detection devices and automatic sprinklers"

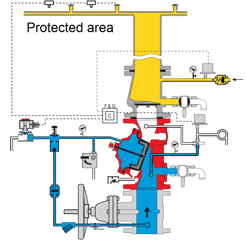

In a double interlock system the electric detection device has to be activated together with a fall in the maintained air pressure in the closed automatic sprinkler pipeline, as at least one sprinkler is activated by a heat source, before water will be released into the sprinkler piping.

In the event that only the electric detection device is activated or only the air pressure switch in the sprinkler piping is activated the main valve will stay closed and the sprinkler piping will stay dry.

Double interlock pre-action systems offer a level of insurance against unnecessary water damage should one of the detection devices be activated through accident or fault, as might happen if a pipe breaks or an automatic sprinkler gets knocked or broken, or an electrical fault in the heat/fire detection device. Therefore Double interlock pre-action systems are often installed where highly valuable or irreplaceable equipment is stored. For example, computer rooms, libraries, museums, or art galleries.

Double interlock pre-action systems contain air or nitrogen in the piping in the protected area and will only fill the system piping if water is to be deployed to fire. For this reason they are also used where the protected area has freezing conditions, where pipes with water would quickly freeze and block the sprinkler piping. Often in such cases pressurized nitrogen is used as nitrogen unlike air will not contain moisture, which can build up, freeze, and block sprinklers. An added advantage of nitrogen is that there will be no oxidization or corrosion within the piping.

The main limitation for double interlock pre-action systems is the time it takes for the water to reach the fire as the pipe is dry and has to fill before water arrives at the fire. This fact restricts the size or volume of piping systems using Double interlock preaction systems

Single interlock pre-action

NFPA 13 "Admits water to sprinkler piping upon operation of detection devices"

The single interlock pre-action system is designed to reduce the time taken to apply extinguishing water while still providing some protection against accidental water deployment in the protected area.

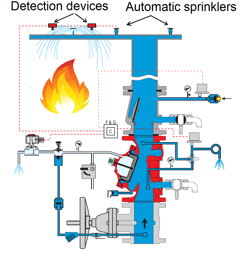

Like the double interlock system, the single interlock valve employs a supplemental electric detection device and automatic sprinklers. It too is designed to be a dry pipe system, with the pipes normally full of air or nitrogen rather than water.

In a single interlock system, the supplemental detection device will typically have a lower temperature rating than the automatic sprinklers. The single interlock system is designed not to wait for the automatic sprinklers to operate to open the main valve, as a double interlock system would, but will open the main valve filling the sprinkler piping with water. This way as soon as the fire grows hot enough to operate an automatic sprinkler, the water will be deployed immediately in the area of the fire with no delay.

Single interlock preaction systems are usually employed in locations where there is less sensitivity to water damage than might be where a double interlock system would be used and a quicker fire response is desired (for instance the protection of human life in a gallery or library.)

Non-interlock pre-action

NFPA 13 "Admits water to sprinkler piping upon operation of detection devices or automatic sprinklers"

A non-interlock pre-action system functions very much like a single interlock system, in that if the supplemental detection device is activated the main valve will open allowing water into the sprinkler piping, ready to be released to the heat source once the heat rises enough to activate the automatic sprinklers. The exception with a non interlock system is that if the automatic sprinklers alone are activated the main valve will open and release water into the protected area without waiting for the confirmation of the electrical detection device. The result is a less precautious system.

In a non interlock system if a sprinkler valve is accidently broken, unlike the single or double interlock systems, the non-interlock will open the valve and allow water into the system piping, releasing water into the protected area. As such the guard against a false alarm releasing water into the protected area is greatly reduced.

The advantages of a non interlock system over a single interlock system are debatable

Choosing the appropriate pre-action system

Pre-action valve systems are more expensive than an ordinary deluge valve system because they are more complex and require significantly more components for proper functioning. However the type of protection they afford makes them the system of choice in many applications.

The true value of a pre-action system is to protect assets that would be badly damaged by water as well as fire, and/or to afford functionality and avoid costly damage or maintenance to pipes in freezing conditions. Deciding which pre-action system to use is a matter of weighing the pros and cons of each system in light of the character of the protected area and what it protects.

Double interlock offers the highest protection against a false alarm. However, there is the issue of delay in pre-action systems that employ a dry sprinkler pipe in the protected area. This concern is addressed by limiting the size of such systems, thereby ensuring a quicker water delivery time. In a larger area or where human safety is a concern you may choose to use a single interlock system to minimize delay in the event of a fire outbreak.

Advantages of BERMAD pre-action valves

BERMAD offers a number of pre-action valve options incorporating our 400 series deluge valves. The advantages of a BERMAD valve include:

- Reliability: BERMAD pre-action valves have no mechanical moving parts and contain unique design features that result in a high level of performance, long life, and minimal down time.

- Time savings: All pre-action valves have to be periodically tested and reset. To reset a clapper valve is very time consuming. Hydraulic valves can be reset very easily in about 1/10th of the time, significantly reducing the cost and time of maintenance. Additionally, our valves can be quickly and easily inspected simply by removing the cover, with no need to disassemble or remove the valve from the line.

- High flow capacity (400Y series): Pre-action systems incorporating the 400Y model deluge valve enjoy the advantage of the exceptionally high flow capacity this valve affords.